Cool thanks. Initially I wanted to make one of those strip one piece adapters that bridges across all the coil positions out of phenolic material but they are too expensive to buy initially to copy. I may just have to buy one of these aluminium single ones which will be a lot cheaper and by the sound of it be a more reliable fit.

Above Forum Ad

Collapse

Announcement

Collapse

No announcement yet.

Louis19's Build Thread

Collapse

X

-

Yup you are right, on the k03 hybrid setup I was running the stock BJX head with the large port manifold that transitioned down with the IE intake manifold spacer. I gave that one to a mate and got a 034motorsport large port spacer to run on the large port head.

Sent from my iPhone using Tapatalk2006 GTI Polo - Big Turbo Build - Louis19's Build Thread

Comment

-

I bought an ecs one piece. Works good and has the holes pre-drilled to run clamps as well.Originally posted by sambb View PostCool thanks. Initially I wanted to make one of those strip one piece adapters that bridges across all the coil positions out of phenolic material but they are too expensive to buy initially to copy. I may just have to buy one of these aluminium single ones which will be a lot cheaper and by the sound of it be a more reliable fit.08 9n3 Polo GTI

Mods: heaps

Comment

-

A friend of a friend has a water jet cutter at his engineering business. They know which sheet works well with the cutter now after doing phenolic spacers for a Renault F4R motor, so we thought we could buy 1 single coil spacer, draw it out and knock out a batch of them in phenolic. It'll cost nearly the same to do 30 as it would 4. I'll keep what I need and sell the rest. I hate paying for the postage/retail on stuff like that that I know I can make myself but at the same time I'm a bit over doing machine-y type stuff at work. That's why I thought phenolic and just pay someone else to do it provided I can at least break even by selling some of the product afterwards.

Comment

-

I had a quick squiz at the picture of the individual spacers on the creationmotorsport site linked on the last page, if I understand your meaning about a single piece, it'd be a easy to measure one up and draw it...Originally posted by sambb View PostA friend of a friend has a water jet cutter at his engineering business. They know which sheet works well with the cutter now after doing phenolic spacers for a Renault F4R motor, so we thought we could buy 1 single coil spacer, draw it out and knock out a batch of them in phenolic. It'll cost nearly the same to do 30 as it would 4. I'll keep what I need and sell the rest. I hate paying for the postage/retail on stuff like that that I know I can make myself but at the same time I'm a bit over doing machine-y type stuff at work. That's why I thought phenolic and just pay someone else to do it provided I can at least break even by selling some of the product afterwards.

though (correct me if I'm wrong), phenolic is an insulator, if you want the coils to run cooler, you really want it made out of aluminium to give it a heat sink - do you want to insulate the coils from the heat of the engine, or do you want to use the engine as a heat sink for the coils? I've never looked at the temperature of the LS1 coils on my mini, I don't know how hot they get...

these are the spacers, right?

Comment

-

Haven't seen the r8 packs but think they're enclosed in a plastic housing and potted in like stock packs. Thermal dissipation from the aluminium/metal spacers wouldn't make much difference as its still insulated to a point.Originally posted by simon k View PostI had a quick squiz at the picture of the individual spacers on the creationmotorsport site linked on the last page, if I understand your meaning about a single piece, it'd be a easy to measure one up and draw it...

though (correct me if I'm wrong), phenolic is an insulator, if you want the coils to run cooler, you really want it made out of aluminium to give it a heat sink - do you want to insulate the coils from the heat of the engine, or do you want to use the engine as a heat sink for the coils? I've never looked at the temperature of the LS1 coils on my mini, I don't know how hot they get...

these are the spacers, right?

[ATTACH=CONFIG]30654[/ATTACH]

The phenolic to me would be a better option as it will also transfer less vibration to the pack along with keeping the heat from the tappet cover further away, although I don't see any need to keep them cool as the actual metal shroud it has to the spark plug would transfer most of the heat.

Comment

-

In the case of using aluminium vs phenolic, yeah as a heatsink material aluminium works best but not in the setting of the engine bay bolted to the rocker cover where even finned aluminium would heatsoak immediately and just become a heat source maybe even worse than the standard set up. I think phenolic would act as an insulator and might not pass all the rocker covers heat onto the neck of the coil.

If I was to make a one off for myself the single piece adapter that takes in all 4 coils would be the easiest to make and I'd do it out of aluminium. But if I'm to do it out of phenolic where the cost of the material is higher, then doing the individual coil adapters would squeeze more units out of a sheet and be more $ efficient + I could buy 1 single coil adapter as a template for not much coin whereas the long quad adapters cost bigtime for what they are. Phenolic is just a different material that if anything may have some slight advantages to aluminium and no real disadvantages that I can see.

At work we have these small heatsink squares. If you were really anal you could glue them onto the tops of the coil themselves with conductive paste which would probably cool them slightly but whether that's even necessary I don't know.

At the end of the day I'll be running water injection which demands a reliable ignition system which is why I went for the R8's. anyway enough thread jacking from me. Louis seems sorted in that regard.

Comment

-

Louis19's Build Thread

I made a trip up to Brissy today to pick up my wastegate and oil line and fittings. Motorsportaccessories in Brisbane had everything I needed and were an absolute pleasure to deal with. I also made up some custom oil drain flanges by cutting the old plates off the old line and getting some -8 fittings welded on.

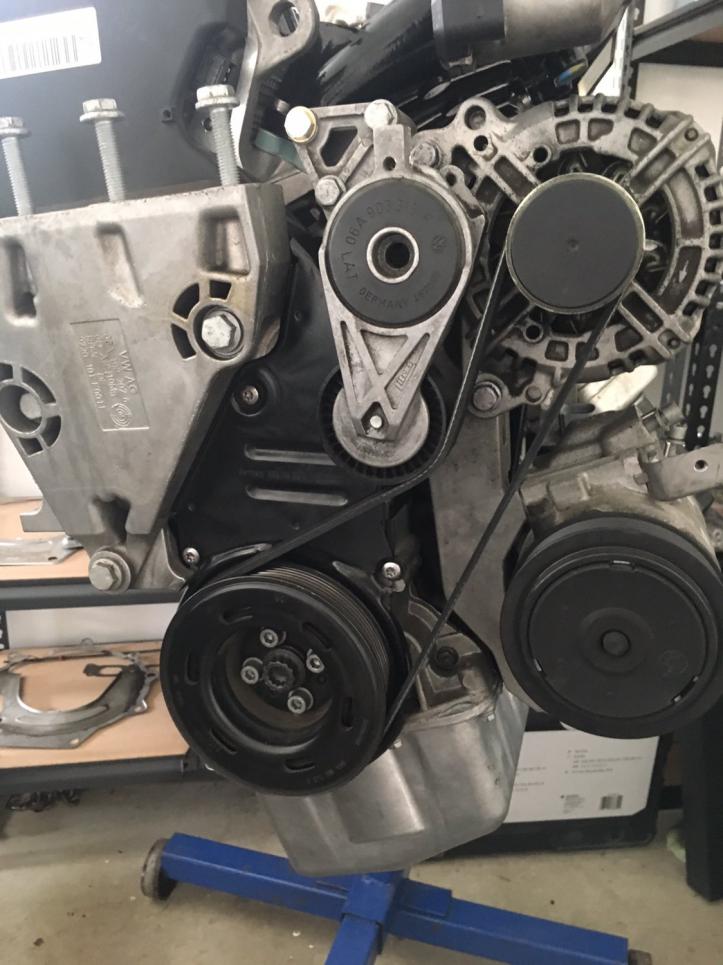

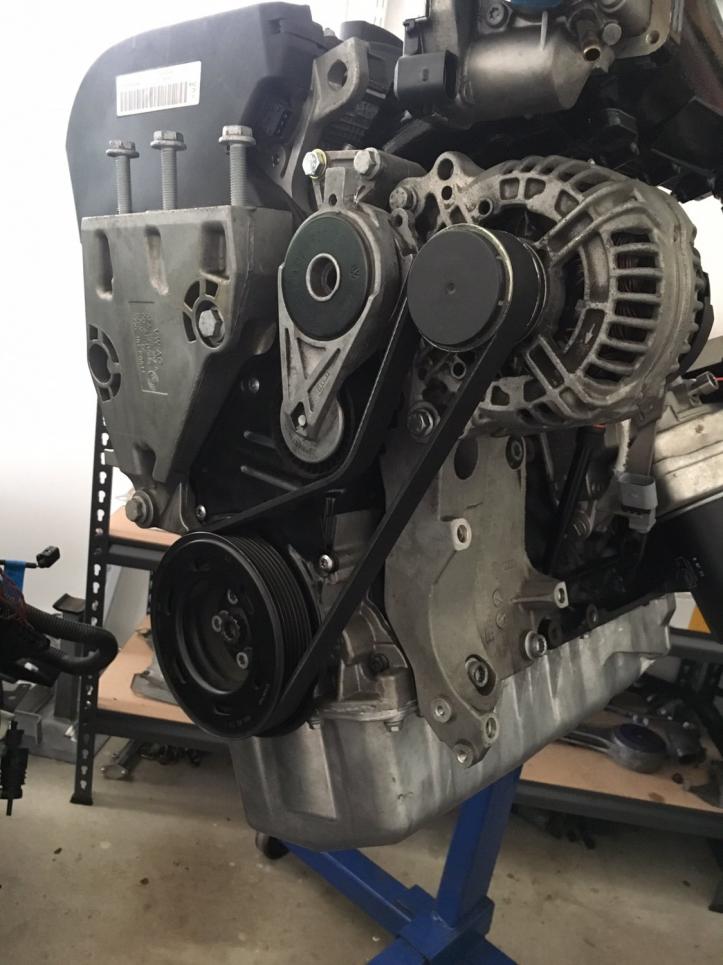

I ended up deleting the aircon in the car due to the pipe work that runs along the firewall being in the direct line of where the exhaust manifold and wastegate will be sitting. The new belt size I measured up and ended up going with was 925mm which fitted brilliantly. Weight wise there's only about 9kg removed from the engine bay between the aircon core, condenser and the lines. An added bonus should be a bit more direct flow over the radiator core with the aircon core no longer sitting in front of it.

More progress and pics to come in the coming days

Last edited by louis19; 17-10-2017, 11:33 PM.2006 GTI Polo - Big Turbo Build - Louis19's Build Thread

Last edited by louis19; 17-10-2017, 11:33 PM.2006 GTI Polo - Big Turbo Build - Louis19's Build Thread

Comment

-

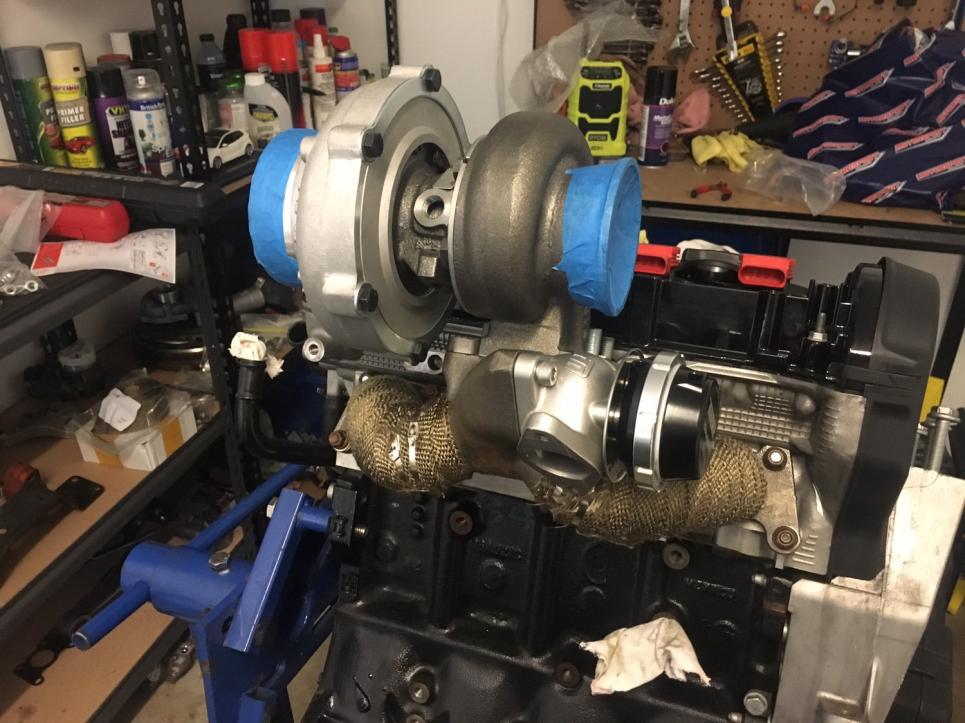

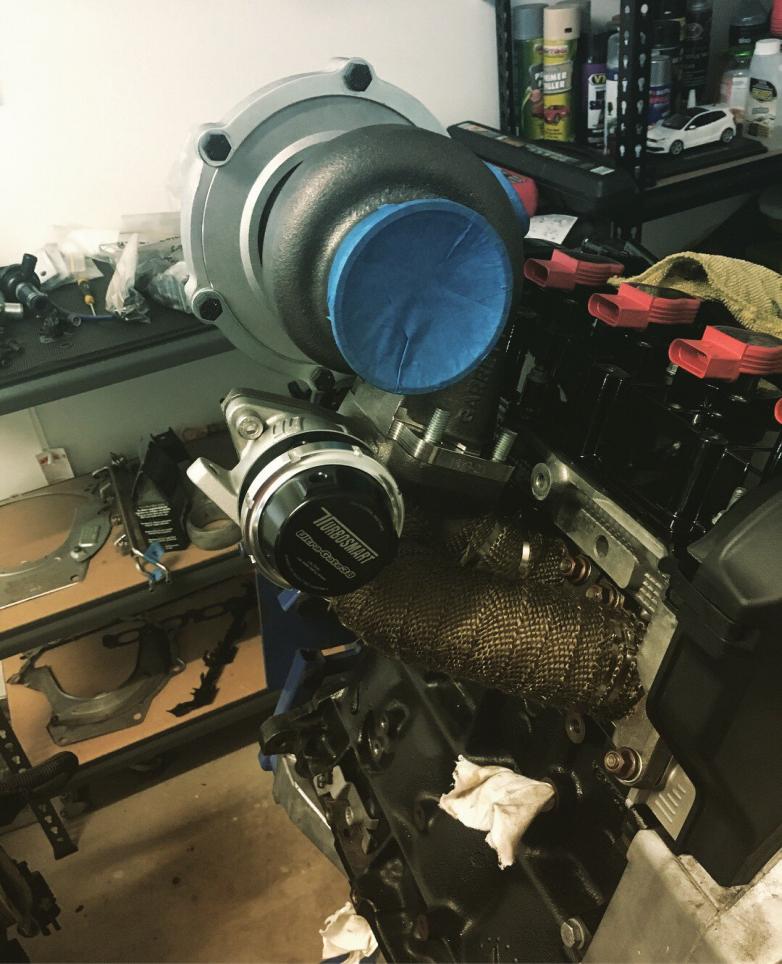

No problem at all, thanks for following. I got to time to do a test fit this afternoon. All is looking pretty good. The main thing is that.. IT FITS!Originally posted by GeorgeMK1 View PostReally loving the updates man, thanks for sharing

A few little things to order to keep me moving forward and a light massage of the firewall, then it shouldn't be too far away from going back into the car with the gearbox attached.

2006 GTI Polo - Big Turbo Build - Louis19's Build Thread

2006 GTI Polo - Big Turbo Build - Louis19's Build Thread

Comment

2025 - Below Forum

Collapse

Comment