Originally posted by Dubstein

View Post

Only The Good Die Young 45

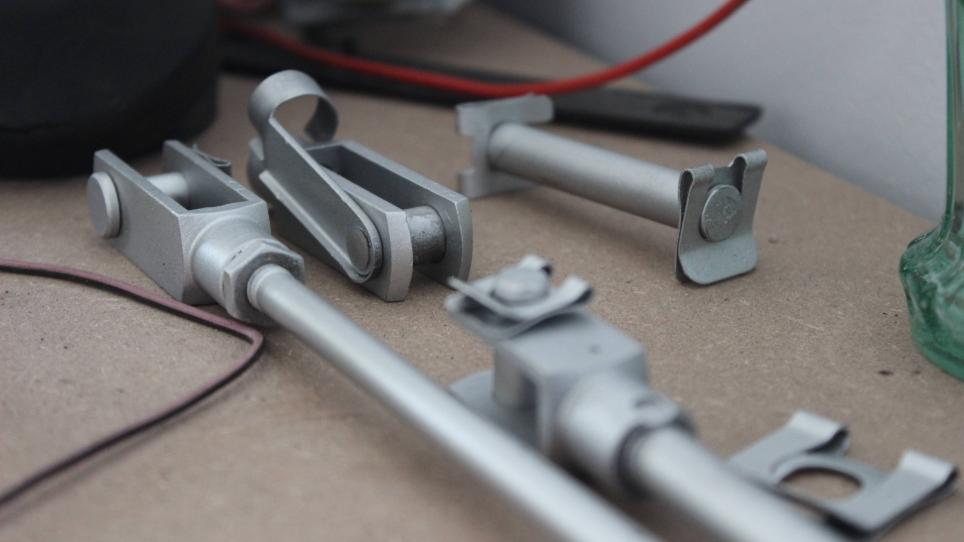

I'm glad to say that i think im now content on how the car is coming along, finally seeing some real progress. Amazing how much work has been done when a coat of primer goes on.. Anyway less words here are some pictures.

I'm glad to say that i think im now content on how the car is coming along, finally seeing some real progress. Amazing how much work has been done when a coat of primer goes on.. Anyway less words here are some pictures.

Comment