Brilliant

Above Forum Ad

Collapse

Announcement

Collapse

No announcement yet.

Little Red Devil

Collapse

X

-

Will be interesting to see what difference the Seat intercooler makes.

Any reason why you chose the billet turbo route over the frankentrubo for future upgrades?

Comment

-

Yeah, can't wait Clay! The main reason for going with Billet is the ballbearing component. It will have the usual hybrid parts Frankenturbo will have such as bigger compressor and turbine wheels and rear custom housing but will have Garrett GT28 characterisitics. This is taken from their site

Billet Turbochargers are an elite true high performance turbocharger built from the highest quality parts and materials. They are lighter, spool faster and can handle higher thrust loads than have ever been achieved in any production turbocharger. Billet Turbo's was the first to utilise a full complement silicon nitride (ceramic) ball bearing system and is still the worlds most advanced turbo ball bearing system.

Billet Turbo’s are available for small engines all the way up to the professional drag racer. Billet Turbochargers produce twin ball bearing turbo’s capable of flowing 2400hp per turbo making Billet Turbochargers the manufacture of the highest flowing twin ball bearing turbo’s in the world.

Conventional ball bearing turbos use steel ball bearings, Phenolic (plastic) bearing cages and GMR turbines. Some brands are still using a single brass caged ceramic ball bearing and journal/bush oil bearing system.

Billet Turbochargers takes the ball bearing turbo to a whole new level.

Billet Turbochargers use perfectly matched aerospace grade twin full complement silicon nitride ball bearing systems and the latest technology compressor wheels and Inconel turbines. Inconel is the most durable material used in conventional production turbochargers.

The perfectly matched aerospace grade twin full complement silicon nitride ball bearing system developed by Billet Turbocharger disregards the need for a bearing cage altogether. With out the need for a bearing cage the Billet Turbochargers ball bearing system has considerably less drag than conventional ball bearing turbo’s.

The Billet Turbochargers silicon nitride balls are 58% lighter, 121% harder, than steel ball bearings, have a truer shape and they can withstand higher speeds, more heat and higher thrust loads. With lighter, truer shaped aerospace grade ball bearings and no bearing cage, then used in conjunction with the latest compressor wheels and Inconel turbines. Billet Turbochargers make more power, spin up faster and can with stand more punishment by design.

The Billet centre cartridge and back plates are a unique advanced light weight, hard anodized precision CNC machined aeronautic grade billet aluminium piece. As well as being functional in strength, heat dissipation and weight saving. They look amazing. The quality of finish and attention to detail is first class. The Billet Turbochargers come in a standard colour range of anodized Red, Blue and Purple.

Billet Turbochargers is leading the way of all high performance ball bearing turbo’s setting new benchmarks in performance, durability and Quality not seen in any other turbo

Billet Turbochargers use the most technologically advanced turbo ball bearing system in the world

• Perfectly matched aerospace grad full complement twin silicon nitride ball bearing system

• Precision CNC machined aeronautic grade billet aluminium centre cartridge.

• Latest technology Inconel turbines

• Latest technology compressor wheels

• Handle higher shaft speeds and thrust loads

• Physically lighter

• Spool faster

• First class finish and look great

• More durable

Frequently Asked Question:

Is the Billet Turbochargers ball bearing system just the same as other ball bearing turbo's ?

Short Answer:

NO!

The Billet Turbochargers ball bearing system is NOT a copy of any other ball bearing turbo. The Billet Turbochargers ball bearing system is an original design developed by Billet Turbochargers. The basic idea for the advanced ball bearing system came from the aerospace sister company Talon AeroSpace. At Talon AeroSpace they develop and manufacture small gas turbine jet engines for defense force uses. The same principles as used in Talon AeroSpace ball bearing jet engines have been carried over to the Billet Turbochargers system. Gas Turbine jet engines have much higher shaft speeds, extreme heat and thrust loads than any turbocharger. These facts led to the unique high performing and robust design of the Billet Turbochargers ball bearing turbochargers.

Comment

-

Okay, sounds like a worthy upgrade path.

Definitley no way i am going to be able to keep up with you after that one goes in with a corresponding tune.

Comment

-

Hahaha, that would be a handful.Originally posted by VWindahouse View PostI'm sure the worlds first Stage 3 Tiggy would fix that

The extra parts required (heavy duty clutch etc) would make it about an 8k job.

Home loan comes first.

Comment

-

Technically it's not racing, just some fun laps and a chance to test out the car and see what it can do safely and having a chat with others after the session.Originally posted by Lock & Load View PostBeen to Wakefield a few times in my Mazda RX8 , but wont be taking my current Mazda RX7 nor the new Polo GTI Anytime soon , leave the racing to you young ones

Just over 2 weeks until we get to see the red rocket in action again (with Seat intercooler, the first true test)

Comment

-

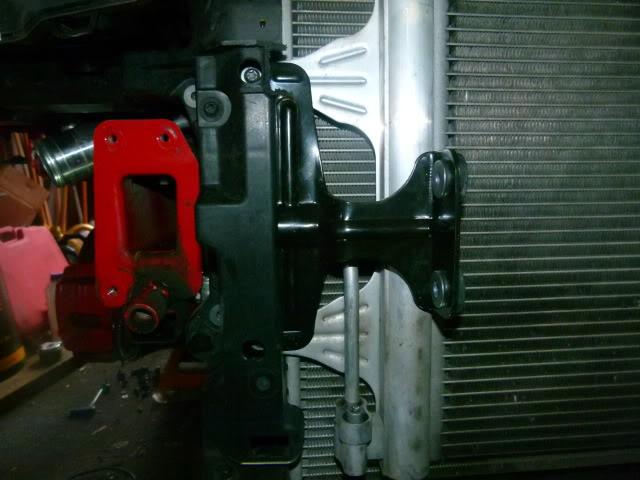

Well with the Seat intercooler you will. Just thought i would add to the thread for Anthony as i had the opportunity to take some pics during the Intercooler install. Its not a straight fit for anyone looking at going this way but , very doable, there was of course a few tricks along the way but you get that with mods. Firstlly removed the Forge unit to make way for the new Stealthy Seat Sport cooler. With the Seat cooler you need the Seat brackets and bolts and of course the cooler. Coupled with the a Forge Seat hose kit. Fitting the brackets would normally need the rad and condensor be removed but i put some access holes in the rad support like below

When the cooler is installed and the pipes go on then you have to re route the map and map wiring loom. There is a useless bracket in there which goes in file 13 ( bin)

Here is the cooler before pipework

Then here is the map fitted with the wiring loom routed differently

This is the map connector on and in place with plenty of slack and no fouling of the map

Here is the loom being moved and reclipped

and here it is all clipped in place

Here is the finished article before the bar cover goes on

with the bar cover and grille then thats a different matter, there is a lot of plastic also goes in file 13. Would take a good few pics to show but if you embark on it you will for sure know what i mean.

With the kit you still use the existing plastic pipe one the hot side that runs under the crank pulley. We will monitor this as its plastic and ive seen even stock ones broken there at the mounting point.

Fitted the new awesome strut brace but unfortunately never took pics of this so will leave it to Ant for that. I can say that was tasky too having to remoave the ECU and scallop the casing to allow fitment but the results were worth it.

Anyway tested the car this morning after it was all back together and man what a hoot!!! this thing is like an ox and im sure the dyno results will prove it. Certainly Butt dyno says yes and i couldnt stop smiling , mind you this happens every time i drive this thing but happened way quicker today.

Looking forward to seeing the figures, but man it goes good.

Cheers

JmacAlba European

Service, Diagnostics and repairs. Mobile Diag available on request

Audi/VW/Porsche Factory trained tech 25+ yrs exp

For people who value experience call 0423965341

Comment

-

oh yeah! Get a container booked Jimmy.

oh yeah! Get a container booked Jimmy.

Comment

2025 - Below Forum

Collapse

my stroker kit and gear set will have to wait also

my stroker kit and gear set will have to wait also

Comment