Frank looking sharp as usual.

Above Forum Ad

Collapse

Announcement

Collapse

No announcement yet.

1980 B1 Passat Project

Collapse

X

-

Got onto this thread via the "DIY Paint - Close Door Job?" thread, and have just spent forty five minutes reading about Frank. It's truly an inspiration to see the level of commitment to detail and quality in your restoration.

Best Wishes.

Comment

-

Frank's carby has been playing up a bit lately and really needs a rebuild.

Just your typical progressive on a TS manifold.

Here's how we solved the problem.

79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

7? MK1 Caddy

79 B1 Passat Dasher Project

12 Amarok

Comment

-

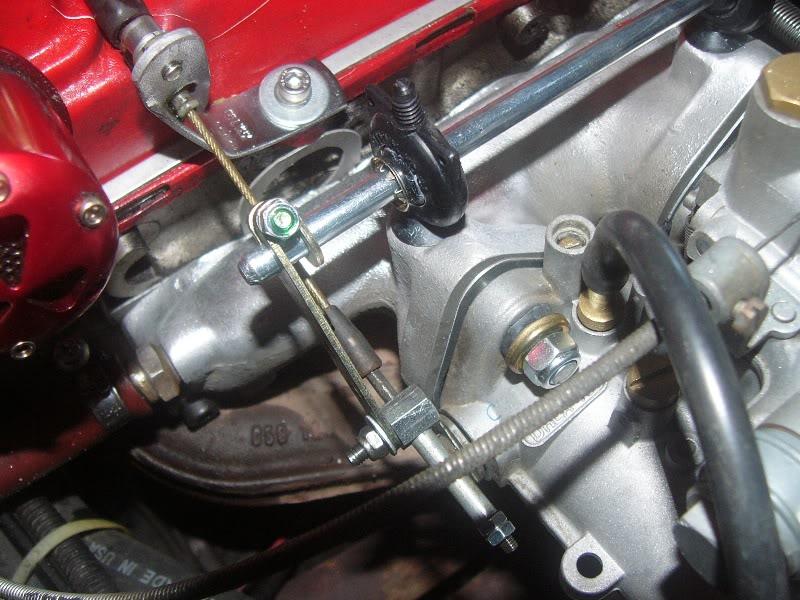

Here's some detail of the installation.

The linkages came up really well.

79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

7? MK1 Caddy

79 B1 Passat Dasher Project

12 Amarok

Comment

-

Some of the ingredients.

79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

7? MK1 Caddy

79 B1 Passat Dasher Project

12 Amarok

Comment

-

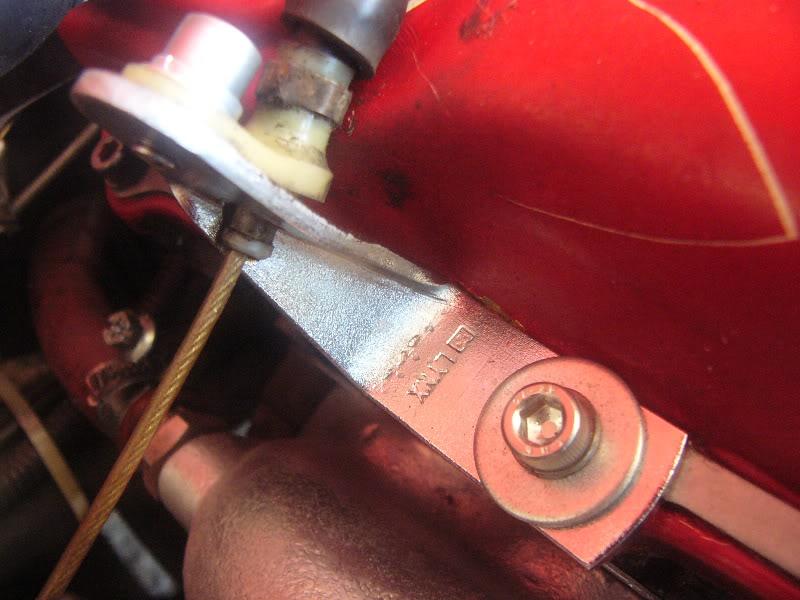

A note on the linkage kit.

Once upon a time Lynx used to manufacture manifolds in Australia. All their manifolds were cast to accept their own linkage kits.

Lynx don't make manifolds any more but they do still make the linkage kits.

So if you ever get a second hand Lynx manifold all you have to do is give the nice people at LYNX a call and place an order. Same place does all the Ramflo bits and pieces.79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

7? MK1 Caddy

79 B1 Passat Dasher Project

12 Amarok

Comment

-

Cheers Mik!Originally posted by mikinoz View PostI check your thread every few weeks Pete and every time I dig your attention to detail more and more. True craftsmanship. Keep at it as it really motivates me for one to strive to improve my skill.79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

7? MK1 Caddy

79 B1 Passat Dasher Project

12 Amarok

Comment

-

But how does it go? I hear you ask.

Jodie's driven it and says it's more responsive and keeps making power high up in the RPM range. Acceleration is better so there's probably a few more horses in it.

The head has been ported, I saw the inlet ports for the first time while installing the cab and it looks like a good job.

The valves themselves look a bit coked up, I'll have to reco the head sometime down the track.

It's pinging a little, I'll drive it tomorrow and back the timing off a bit.

79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

7? MK1 Caddy

79 B1 Passat Dasher Project

12 Amarok

Comment

-

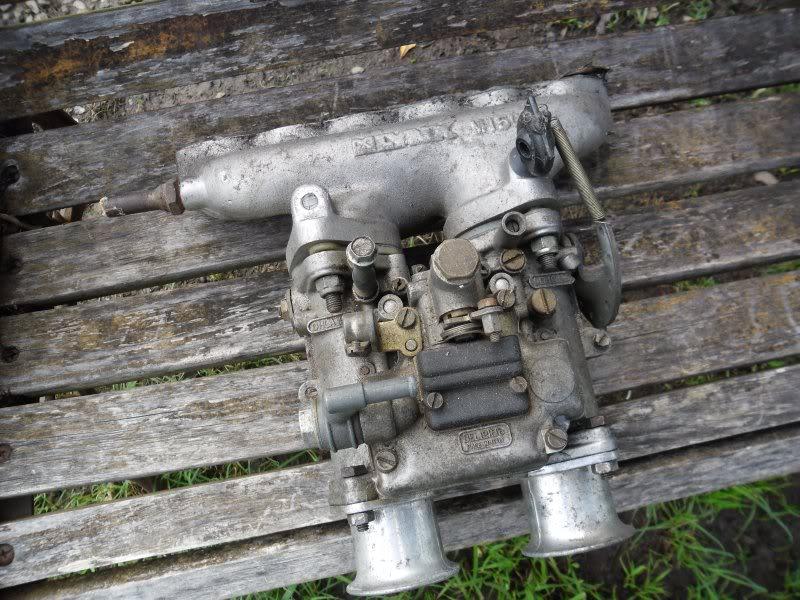

Here is how the carb looked when I bought it.

It was in really good nick, all I had to do was give it a good clean.79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

7? MK1 Caddy

79 B1 Passat Dasher Project

12 Amarok

Comment

-

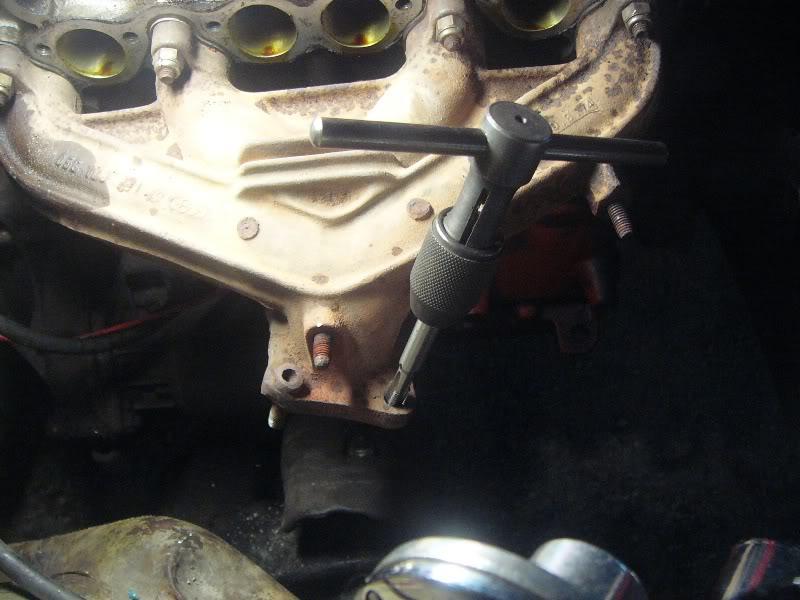

I've had to repair the down pipe previously.

We managed to pick up a new downpipe at SEDF but the outlet size is wrong for the 2" system we had fitted.

WHile I had the inlet manifold off I removed the current down pie and test fitted the new pipe so I could weld on the adapting piece.

The plan is to get the new pipe ceramic coated.

Of course one of the exhaust manifold threads stripped out, so I had to drill it out and helicoil it.

Hopefully we'll drop the pipe off for coating tomorrow.79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

7? MK1 Caddy

79 B1 Passat Dasher Project

12 Amarok

Comment

-

I wondered about the pipe today when I saw it, but forgot to ask!

I can attest, it sounds so much better in real life! Looks mega neat too.

Comment

-

That's the way I likes it, Pete.

APR Tuned | KW Suspension | INA Engineering | Mocal Oil Control |

Website: http://www.tprengineering.com

Email: chris@tprengineering.com

Comment

-

Dropped the down pipe off for ceramic coating today and got a few miles up on the Dellorto.

I wound the timing back 2° as it was pinging a little, it was about 3° advanced in any case.

When I was trial fitting the down pipe yesterday I noticed the front exhaust hanger bracket was broken. I should have fixed it then as today it developed quite a rattle.

The bracket is bolted to the gearbox on top of the rear mount bracket.

I'd been meaning to swap out the rear mount so it seemed best to fix both at once.

All pretty straight forward until I removed the lowest bolt and discovered that the bolt hole is actually drilled right through to the inside of the box.

Got a 8mm gush of oil to the forehead.

The rest was a pretty easy job to re weld the two halves of the exhaust bracket together and bolt it all back into place.

Carby works extremely well, really smooth power delivery, much better than the progressive that was on it.79 MK1 Golf Wreck to Race / 79 MK1 Golf The Red Thread / 76 MK1 Golf Kamei Race Car

7? MK1 Caddy

79 B1 Passat Dasher Project

12 Amarok

Comment

2025 - Below Forum

Collapse

Comment