I just received some info from Roger "Riceman" Lee about DCOEs. He offered me a base spec for what i'm building, which was really nice of him..

It may not live very long at 11 to 1 CR, but that is your motor. Set the Fuel Pressure at 3 PSI and not over 3.5 PSI. Any high, it will bend the Floats out of adjustment.

180 Degree Radius Air Horns about 50mm long work alot better than the... stock Weber Air Horns. Just remember that when air contacts a longer air horn surface radius lip, the better the flow.

Make sure you have vibration dampeners between the Carbs and Manifolds. The kind to use are molded rubber tube with flanges on the ends, about 25mm long. You will need four of them. I used ones made for a VOLVO. Take a Manifold gasket with you to a Volve dealer to match up the size. DO NOT use the double O-ring single plastic spacer type, they leak !

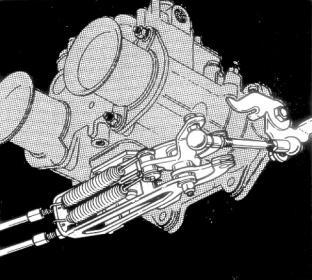

4.5 Aux Venturi and wire tie the set screws, 33 or 34 mm Main choke tubes (Venturi). 2.00 Air Corrector Jets, F-9 Emulsion tubes, 1.70 Main jet. These are just suggestions

Idle set screws should be about 3/4 turns out from closed. These must be set with a Tach. If the RPM rises when the # 1 screw is turned out 1/8 of a turn(fatter), the idle mixture is too lean. Turn the # 2 idle mixture screw the same amount and see what happens. Idle speed should be 1000 RPM.

If the RPM drops while doing this, it is too fat. You want the idle set screw set at the point of the highest rpm ( 1000 base rpm) before the rpm drops.

The motor should be at running temp when doing this and the carbs are syncranized, checking # 1 & # 3 barrels using a Uni-Syn flow gauge.

180 Degree Radius Air Horns about 50mm long work alot better than the... stock Weber Air Horns. Just remember that when air contacts a longer air horn surface radius lip, the better the flow.

Make sure you have vibration dampeners between the Carbs and Manifolds. The kind to use are molded rubber tube with flanges on the ends, about 25mm long. You will need four of them. I used ones made for a VOLVO. Take a Manifold gasket with you to a Volve dealer to match up the size. DO NOT use the double O-ring single plastic spacer type, they leak !

4.5 Aux Venturi and wire tie the set screws, 33 or 34 mm Main choke tubes (Venturi). 2.00 Air Corrector Jets, F-9 Emulsion tubes, 1.70 Main jet. These are just suggestions

Idle set screws should be about 3/4 turns out from closed. These must be set with a Tach. If the RPM rises when the # 1 screw is turned out 1/8 of a turn(fatter), the idle mixture is too lean. Turn the # 2 idle mixture screw the same amount and see what happens. Idle speed should be 1000 RPM.

If the RPM drops while doing this, it is too fat. You want the idle set screw set at the point of the highest rpm ( 1000 base rpm) before the rpm drops.

The motor should be at running temp when doing this and the carbs are syncranized, checking # 1 & # 3 barrels using a Uni-Syn flow gauge.

Comment