I meant taking 15mm off the rubber insert. requires a little bit of modification of the insert 'housing' (similar to what you did with the front one, with the drilling and tapping of the central rod)

I've got a mk 3 subframe, (VR swap) and all I did was chop down the rear mount around 15 or 20mm.

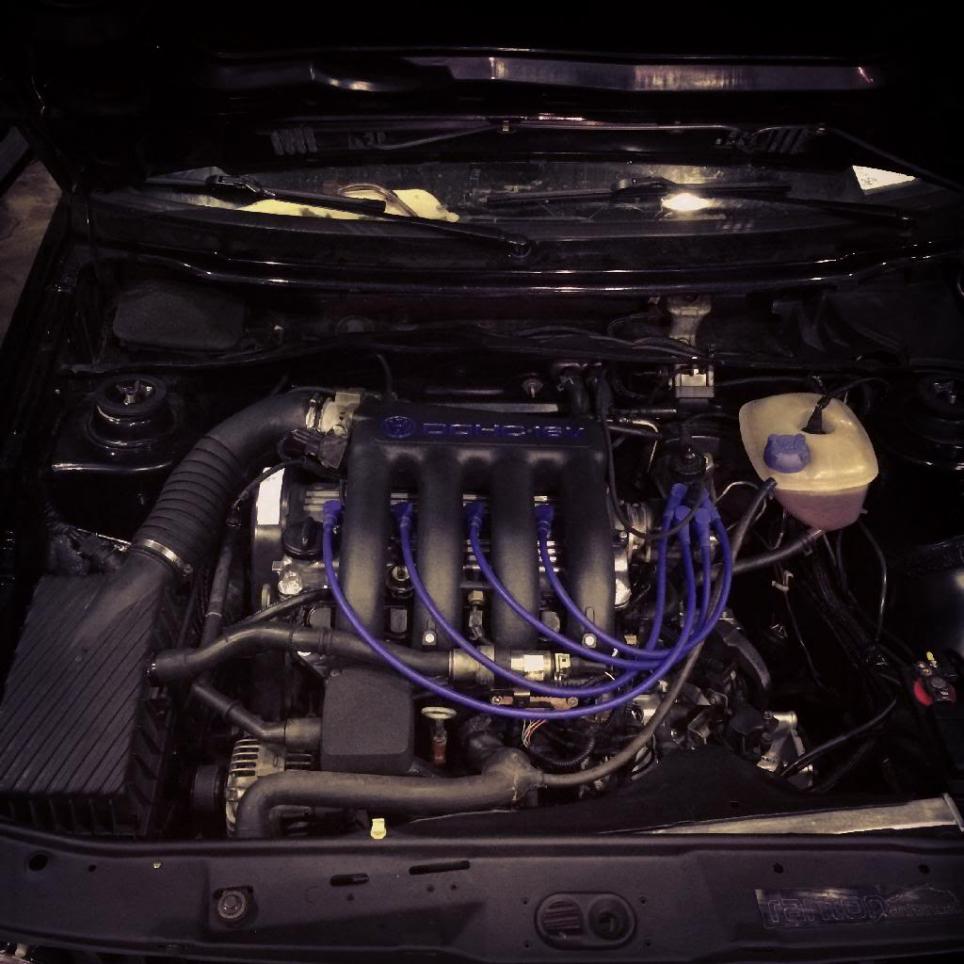

I used to have a mk 2 front engine mount (unmodified and standard) and modified the bracket (hybrid mk 2/3) to suit the 02A. Using the standard mk 2 crossmemeber. I found that the engine had unacceptable amounts of rock., ie when coming off the throttle at high rpm.

I have since upgraded to a toledo/passat/corrado front crossmemeber (mk 2 fitment, but with a mk 3 mount system) and run a factory bracket (unmodified) with a mk 3 BFI insert. Much better, no issues with rubbing/knocking.

I've got a mk 3 subframe, (VR swap) and all I did was chop down the rear mount around 15 or 20mm.

I used to have a mk 2 front engine mount (unmodified and standard) and modified the bracket (hybrid mk 2/3) to suit the 02A. Using the standard mk 2 crossmemeber. I found that the engine had unacceptable amounts of rock., ie when coming off the throttle at high rpm.

I have since upgraded to a toledo/passat/corrado front crossmemeber (mk 2 fitment, but with a mk 3 mount system) and run a factory bracket (unmodified) with a mk 3 BFI insert. Much better, no issues with rubbing/knocking.

Comment