Yes Eibach Aust were really great to deal with!

Ordered one day...delivered the next.

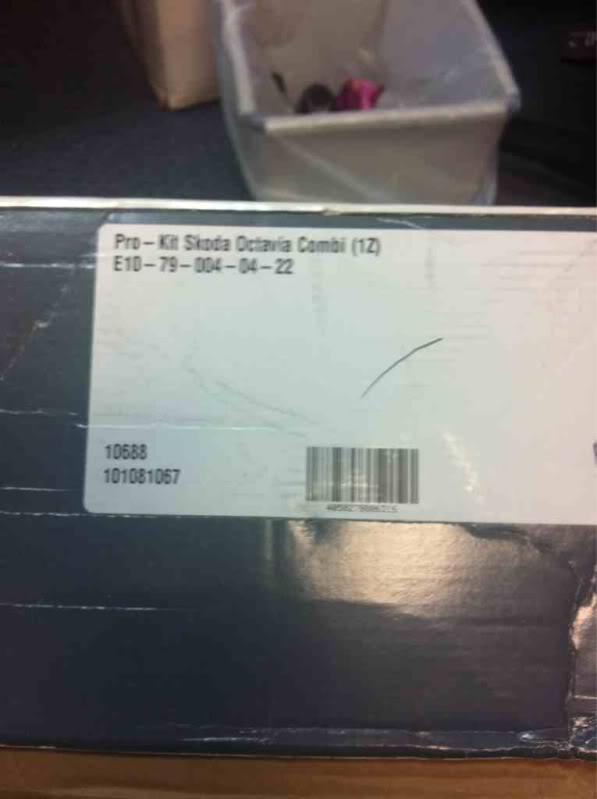

Items are of a very high quality and fitment was straightforward for someone who knows what they are doing....

Ordered one day...delivered the next.

Items are of a very high quality and fitment was straightforward for someone who knows what they are doing....

Comment