I'm glad to share with all owners of DSG 7 who wants to perform basic setting and initial learning in DSG 7

this original procedure:

this original procedure:

Technical product information

Transaction No.: 2025490/1

3511, 1P, 5P, 6J, Basic setting and initial learning in DSG (0AM - 7sp.) gearboxes

Release date: 12-Apr-2011

Customer statement / workshop findings

The basic setting in DSG (0AM – 7sp.) gearboxes cannot be performed with guided fault finding.

Technical background

Various causes have been detected, including the main reason of low battery voltage.

On completion of the basic settings, the handling of the transmission does not improve.

Production change

- - -

Measure

ATTENTION!

- Connect a battery charger to ensure the power supply of the vehicle.

- Check that the diagnostic connector is correctly plugged in.

- Update the VAS 505X to the most recent version available.

- The transmission must have an ATF temperature of more than 60° C.

Proceed as follows to perform the basic setting:

1.- Vehicle at standstill

2.- Engine switched off

3.- Gear lever in Parking position

4.- Handbrake on

5.- Brake pedal depressed

With the VAS 505X connected and the ignition on (Current 15):

1.- Enter Self-diagnosis

2.- Select Transmission

3.- Basic settings

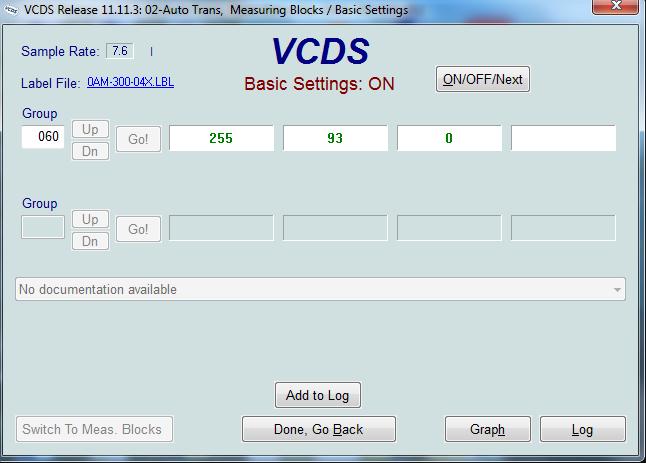

4.- Enter value block 60 and Q

The following reference values are displayed:

253 1 12: The basic setting has commenced

4 0 0: Start the engine

254 0 0: The basic setting has been successfully completed

255 0 0: The basic setting was interrupted

If value 254 is displayed, this indicates that the basic setting has ended successfully, then

switch off the ignition and remove the key, 3 seconds.

ATTENTION!

When test driving the vehicle, traffic conditions must be observed.

Start the vehicle and test drive vehicle for the initial learning of the DSG (0AM – 7sp.) gearbox.

Test drive:

1-Place the gear lever in position D and perform two driving cycles

forwards from 0 km/h to 2nd gear.

Place the gear lever in position R and perform two driving cycles in

reverse (drive for a few metres).

2-Place the gear lever in Tiptronic.

Drive in all gears including reverse gear (R).

Drive in each gear for at least 3 seconds.

3-Place the gear lever in Tiptronic.

Alternate between an odd number gear (3 or 5 or 7) and an even number gear

(4 or 6).

Keep the engine speed between 2000 and 4500 rpm for approximately 5

minutes in each odd and even number gear.

Repeat twice.

Continue test driving with different acceleration percentages.

The Mechatronics control unit must give the maximum acceleration values for a moment.

The vehicle maximum speed must not be reached.

4-Lastly, test drive the vehicle with the customer and confirm the improvements in the

DSG (0AM – 7sp.) gearbox gears.

Drive in D (Drive) and R (Reverse).

If the gears jerk or are harsh, repeat step 3.

Check value blocks 180-1 and 200-1. The number should be at least 3

for each clutch adaptation.

It is not possible to recommend the class and form or the required length.

An unjustified repair or replacement of the part may lead to the refusal of the warranty claim.

Warranty accounting instructions

TA no. / Anomaly / Manufacturer: 3511 / 0040 / …

No. of work position Description of work position Time Units (TU)

01 50 00 00 Guided fault finding/guided function According to diagnosis log. 1)

1) The times indicated are only applicable to this TPI. When submitting the warranty application, please include the number of the TPI used to streamline the process.

Parts information

When necessary, consult the genuine parts catalogue to obtain the part in its most updated form.

Transaction No.: 2025490/1

3511, 1P, 5P, 6J, Basic setting and initial learning in DSG (0AM - 7sp.) gearboxes

Release date: 12-Apr-2011

Customer statement / workshop findings

The basic setting in DSG (0AM – 7sp.) gearboxes cannot be performed with guided fault finding.

Technical background

Various causes have been detected, including the main reason of low battery voltage.

On completion of the basic settings, the handling of the transmission does not improve.

Production change

- - -

Measure

ATTENTION!

- Connect a battery charger to ensure the power supply of the vehicle.

- Check that the diagnostic connector is correctly plugged in.

- Update the VAS 505X to the most recent version available.

- The transmission must have an ATF temperature of more than 60° C.

Proceed as follows to perform the basic setting:

1.- Vehicle at standstill

2.- Engine switched off

3.- Gear lever in Parking position

4.- Handbrake on

5.- Brake pedal depressed

With the VAS 505X connected and the ignition on (Current 15):

1.- Enter Self-diagnosis

2.- Select Transmission

3.- Basic settings

4.- Enter value block 60 and Q

The following reference values are displayed:

253 1 12: The basic setting has commenced

4 0 0: Start the engine

254 0 0: The basic setting has been successfully completed

255 0 0: The basic setting was interrupted

If value 254 is displayed, this indicates that the basic setting has ended successfully, then

switch off the ignition and remove the key, 3 seconds.

ATTENTION!

When test driving the vehicle, traffic conditions must be observed.

Start the vehicle and test drive vehicle for the initial learning of the DSG (0AM – 7sp.) gearbox.

Test drive:

1-Place the gear lever in position D and perform two driving cycles

forwards from 0 km/h to 2nd gear.

Place the gear lever in position R and perform two driving cycles in

reverse (drive for a few metres).

2-Place the gear lever in Tiptronic.

Drive in all gears including reverse gear (R).

Drive in each gear for at least 3 seconds.

3-Place the gear lever in Tiptronic.

Alternate between an odd number gear (3 or 5 or 7) and an even number gear

(4 or 6).

Keep the engine speed between 2000 and 4500 rpm for approximately 5

minutes in each odd and even number gear.

Repeat twice.

Continue test driving with different acceleration percentages.

The Mechatronics control unit must give the maximum acceleration values for a moment.

The vehicle maximum speed must not be reached.

4-Lastly, test drive the vehicle with the customer and confirm the improvements in the

DSG (0AM – 7sp.) gearbox gears.

Drive in D (Drive) and R (Reverse).

If the gears jerk or are harsh, repeat step 3.

Check value blocks 180-1 and 200-1. The number should be at least 3

for each clutch adaptation.

It is not possible to recommend the class and form or the required length.

An unjustified repair or replacement of the part may lead to the refusal of the warranty claim.

Warranty accounting instructions

TA no. / Anomaly / Manufacturer: 3511 / 0040 / …

No. of work position Description of work position Time Units (TU)

01 50 00 00 Guided fault finding/guided function According to diagnosis log. 1)

1) The times indicated are only applicable to this TPI. When submitting the warranty application, please include the number of the TPI used to streamline the process.

Parts information

When necessary, consult the genuine parts catalogue to obtain the part in its most updated form.

Comment