Recently i have had quite a few people ask me about intercoolers and i would like to share some thoughts and detail.

Generally speaking any form of forced induction engine benefits from intercoolers.

The primary function is to cool or reduce the air intake temp being introduced into the engine.

All Turbo and superchargers increase the temp of the intake air of a engine purely by compressing the air to start with

Compressing air generates heat which a simple fact.

The more compressed it is the more heat is generated, ie the greater the PSI the hotter it gets.

The hotter the air gets, as its introduced into a engine, the less power it will actually make.

Now lets take say 10 psi of boost feed it into a intercooler, and you may measure on the intake of intercooler say 70deg C, but on outlet of intercooler it may measure 30deg C the resultant temperature drop is called efficiency of the intercooler, for the previous example works out to 42% efficient.

Now there are various types of intercoolers out there. there most common ones are air to air intercoolers based on two basic constructions, Bar and Plate, and Tube & Fin.

There are also air to water of varying designs including the new type with cood results called the laminova.

But for this discussion we will concentrate on the air to air type as that is what is mostly used in most road cars.

Bar and plate rely in think pieces of aluminium which is utilized as a "heat sink" and passed the air between the plates.

These typically are a little cheaper to make and cool well in Drag car type applications, where there is little air flow at stationary position and the thick aluminium plates take a little time to heat up allowing them good initial efficiency for the duration of a drag.

Tube and fin, well there are basically a extruded aluminium tube with internal fins, there are made to maximize the surface contact of the air to aluminium,

there are efficient when surrounding air passes though the core to radiate the heat, which reasonable air flow and good design extrusion they are shown to be more efficient than bar and plate. At a standstill or little air flow

they can "heat soak" more easily than bar and plate, but become for efficient when vehicle is moving.

So the other factor comes in effciency is the delta factor which is rate of change. So what can also bees seen from this is if a bar and plate take longer to heat up, it will also take longer to cool down.

So varying intercoolers all have their pros and cons and comes down to the real application.

Now testing of intercoolers.

Well we have to look at real world application.

ie that is a Road car running say a turbo.

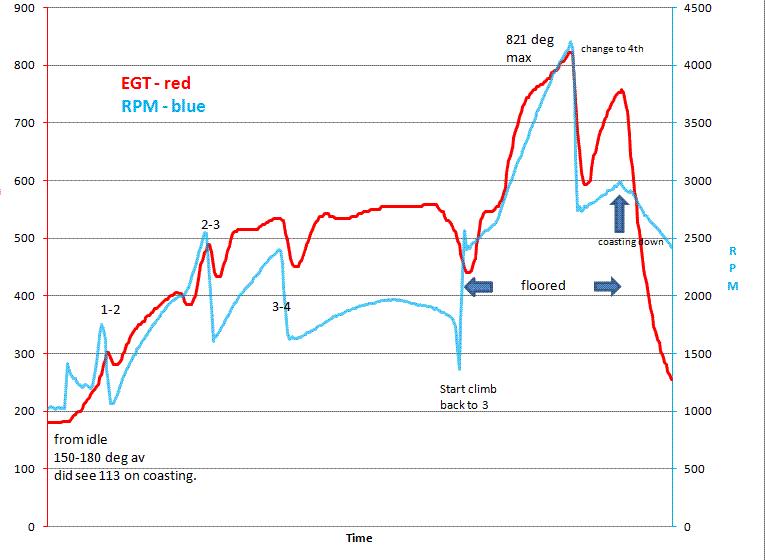

Now to test a intercooler, the absolute best way is setting up temperature sensor on intake and outlet of intercooler whilst driving.

This way you can mesure exactly what is happening whilst driving taking into account the effect of outside air flow at speeds you are driving at.

In car and real driving conditions are the only way to accurately see how it is working.

I am yet to see any company irrespective of what they may design and test inside a workshop/factory, go out are nothing fails and win a race..

All top companies will fit out the final product with a mass load of data Acquisition and measure in on the road, racetrack or what ever and make changes accordingly.

This bring me to the topic of testing on a dyno.

This is all well and fine, however 99% of chassis dyno setups have insufficient air flow to simulate road conditions.

Most chassis dyno have around 8-12 mph fan pointed into one point of the car.

But what does a car on the road experience?

drving every where 8-12 mph?

Oh no, between 35mph-60mph most common.

race or track car 60mph to 240 mph?

So what effects these speed differences make on intercoolers between chassis dyno fan and a car on the road?

A lot of change in efficiency!

The less boost you run, the less work the intercooler needs to do, the less likely you will heatsoak your intercooler and the less power you will loose.

On the other hand the more boost you run, the harder your intercooler has to work and the more critical the air flow through the intercooler becomes to dissipate the heat.

If we use a worst test example say a stock car running stock boost level

and put it on a chassis dyno with only a 10 mph fan, you will find you do repeated runs and the intercooler does not heat soak too much and only a small power is lost with consecutive runs.

Now increase the boost level.

run the same again, you will see the intercooler heat soaks faster and more power is lost.

So then is this going to happen on the road?

No where near what was shown on dyno!!

on the road you will have far more air going through intercooler,

yes it will still heat soak a little faster than at stock levels, how ever you will have a reasonable amount of air going through the core to aid in cooling.

So if you do a measurement of air temps both on the dyno and on the road, you will see the temps are totally different.

You may all check this yourselves with VCDS cable and software in logging mode recording the air intake temps, and you will see the differences between on road and chassis dyno.

Now simple answer could be why not get say a 60 mph fan.

well its not practical in many workshops, firstly 60mph wind would blow you over, rip of the hood from the car and blow other stuff around.

Second, what about cars with side mount intercooler?

well most workshops have one fan directed at radiator, so what about air to sidemounts? Well they got little hope of working efficently.

Take a look at a F1 car, left idling at stationary the engine will overheat, so when they need to run a car for stationary for a extended time, they clip on front of air ducts a electric fan to keep running air through core to stop car from overheating.

No do not take me wrong here, any extra intercooling that is modified on a turbo or supercharged car will have some sort of benefit, you just have to make sure its the right setup for the right application.

Going by some chassis dyno test alone is a waste of time and the results are meaning less.

Many chassis dyno results of product testing is flawed as those tests alone as you can see to not replicate real vehicle road conditions.

I suppose thats why they make wind tunnels!!

The best setup is a speed controlled wind tunnel, where you can simulate the different real road air flow and varying speeds.

Generally speaking any form of forced induction engine benefits from intercoolers.

The primary function is to cool or reduce the air intake temp being introduced into the engine.

All Turbo and superchargers increase the temp of the intake air of a engine purely by compressing the air to start with

Compressing air generates heat which a simple fact.

The more compressed it is the more heat is generated, ie the greater the PSI the hotter it gets.

The hotter the air gets, as its introduced into a engine, the less power it will actually make.

Now lets take say 10 psi of boost feed it into a intercooler, and you may measure on the intake of intercooler say 70deg C, but on outlet of intercooler it may measure 30deg C the resultant temperature drop is called efficiency of the intercooler, for the previous example works out to 42% efficient.

Now there are various types of intercoolers out there. there most common ones are air to air intercoolers based on two basic constructions, Bar and Plate, and Tube & Fin.

There are also air to water of varying designs including the new type with cood results called the laminova.

But for this discussion we will concentrate on the air to air type as that is what is mostly used in most road cars.

Bar and plate rely in think pieces of aluminium which is utilized as a "heat sink" and passed the air between the plates.

These typically are a little cheaper to make and cool well in Drag car type applications, where there is little air flow at stationary position and the thick aluminium plates take a little time to heat up allowing them good initial efficiency for the duration of a drag.

Tube and fin, well there are basically a extruded aluminium tube with internal fins, there are made to maximize the surface contact of the air to aluminium,

there are efficient when surrounding air passes though the core to radiate the heat, which reasonable air flow and good design extrusion they are shown to be more efficient than bar and plate. At a standstill or little air flow

they can "heat soak" more easily than bar and plate, but become for efficient when vehicle is moving.

So the other factor comes in effciency is the delta factor which is rate of change. So what can also bees seen from this is if a bar and plate take longer to heat up, it will also take longer to cool down.

So varying intercoolers all have their pros and cons and comes down to the real application.

Now testing of intercoolers.

Well we have to look at real world application.

ie that is a Road car running say a turbo.

Now to test a intercooler, the absolute best way is setting up temperature sensor on intake and outlet of intercooler whilst driving.

This way you can mesure exactly what is happening whilst driving taking into account the effect of outside air flow at speeds you are driving at.

In car and real driving conditions are the only way to accurately see how it is working.

I am yet to see any company irrespective of what they may design and test inside a workshop/factory, go out are nothing fails and win a race..

All top companies will fit out the final product with a mass load of data Acquisition and measure in on the road, racetrack or what ever and make changes accordingly.

This bring me to the topic of testing on a dyno.

This is all well and fine, however 99% of chassis dyno setups have insufficient air flow to simulate road conditions.

Most chassis dyno have around 8-12 mph fan pointed into one point of the car.

But what does a car on the road experience?

drving every where 8-12 mph?

Oh no, between 35mph-60mph most common.

race or track car 60mph to 240 mph?

So what effects these speed differences make on intercoolers between chassis dyno fan and a car on the road?

A lot of change in efficiency!

The less boost you run, the less work the intercooler needs to do, the less likely you will heatsoak your intercooler and the less power you will loose.

On the other hand the more boost you run, the harder your intercooler has to work and the more critical the air flow through the intercooler becomes to dissipate the heat.

If we use a worst test example say a stock car running stock boost level

and put it on a chassis dyno with only a 10 mph fan, you will find you do repeated runs and the intercooler does not heat soak too much and only a small power is lost with consecutive runs.

Now increase the boost level.

run the same again, you will see the intercooler heat soaks faster and more power is lost.

So then is this going to happen on the road?

No where near what was shown on dyno!!

on the road you will have far more air going through intercooler,

yes it will still heat soak a little faster than at stock levels, how ever you will have a reasonable amount of air going through the core to aid in cooling.

So if you do a measurement of air temps both on the dyno and on the road, you will see the temps are totally different.

You may all check this yourselves with VCDS cable and software in logging mode recording the air intake temps, and you will see the differences between on road and chassis dyno.

Now simple answer could be why not get say a 60 mph fan.

well its not practical in many workshops, firstly 60mph wind would blow you over, rip of the hood from the car and blow other stuff around.

Second, what about cars with side mount intercooler?

well most workshops have one fan directed at radiator, so what about air to sidemounts? Well they got little hope of working efficently.

Take a look at a F1 car, left idling at stationary the engine will overheat, so when they need to run a car for stationary for a extended time, they clip on front of air ducts a electric fan to keep running air through core to stop car from overheating.

No do not take me wrong here, any extra intercooling that is modified on a turbo or supercharged car will have some sort of benefit, you just have to make sure its the right setup for the right application.

Going by some chassis dyno test alone is a waste of time and the results are meaning less.

Many chassis dyno results of product testing is flawed as those tests alone as you can see to not replicate real vehicle road conditions.

I suppose thats why they make wind tunnels!!

The best setup is a speed controlled wind tunnel, where you can simulate the different real road air flow and varying speeds.

Comment