I could powdercoat a few of em at work if you were closer!

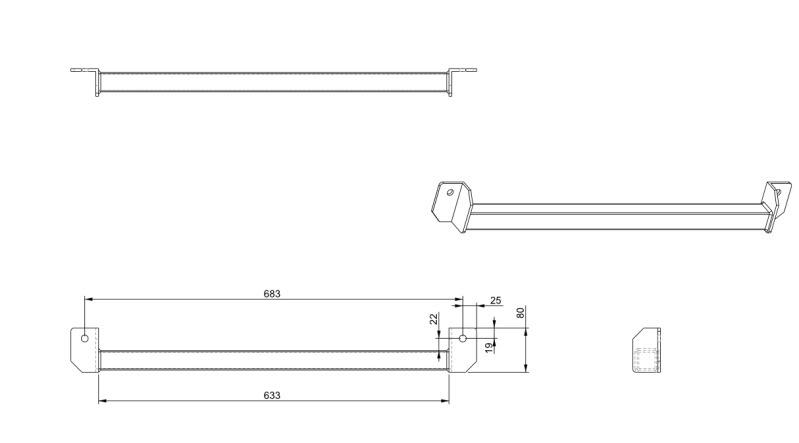

That mint red UK Cabby that is/was for sale had a perfectly straight bar, looked homemade (the same way I'd make it).

Trying to find the picture of it!

That mint red UK Cabby that is/was for sale had a perfectly straight bar, looked homemade (the same way I'd make it).

Trying to find the picture of it!

lol.

lol.

Comment