I thought that it would be nice to have DIY thread for T4.

1996 - 2003

2.4 SD

Engine oil ......... 5.5L (Penrite HPR Diesel15 or HPR Diesel5)

Oil filter ...........

Air filter ...........

Fuel Filter ........

Polen filter .......

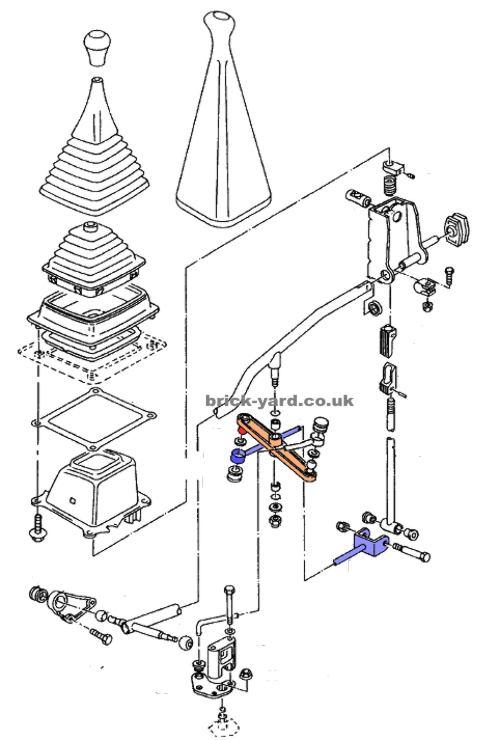

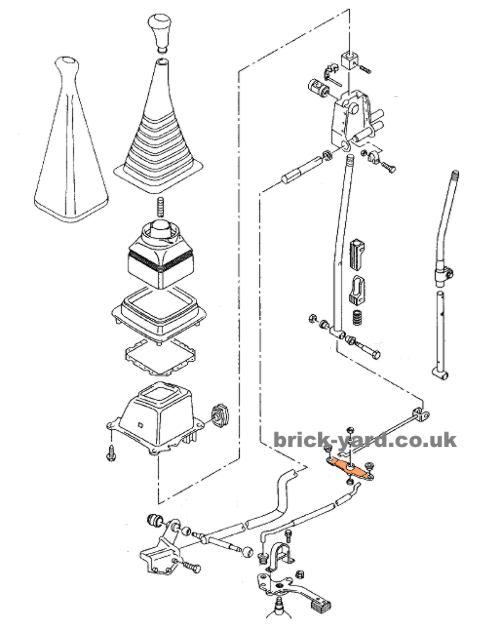

Gear oil ........... 2.0L (Penrite Transxle 75)

ATF ................ G 052 162 A2

Coolant ........... 11.5L (VW G12)

TOW BAR QUESTION

Aftermarket Catalytic Converter http://www.microfreshfilters.com.au/

ENTERING THE RADIO CODE 1998 EURVOX CASSETE RADIO

Feel free to add more information.

1996 - 2003

2.4 SD

Engine oil ......... 5.5L (Penrite HPR Diesel15 or HPR Diesel5)

Oil filter ...........

Air filter ...........

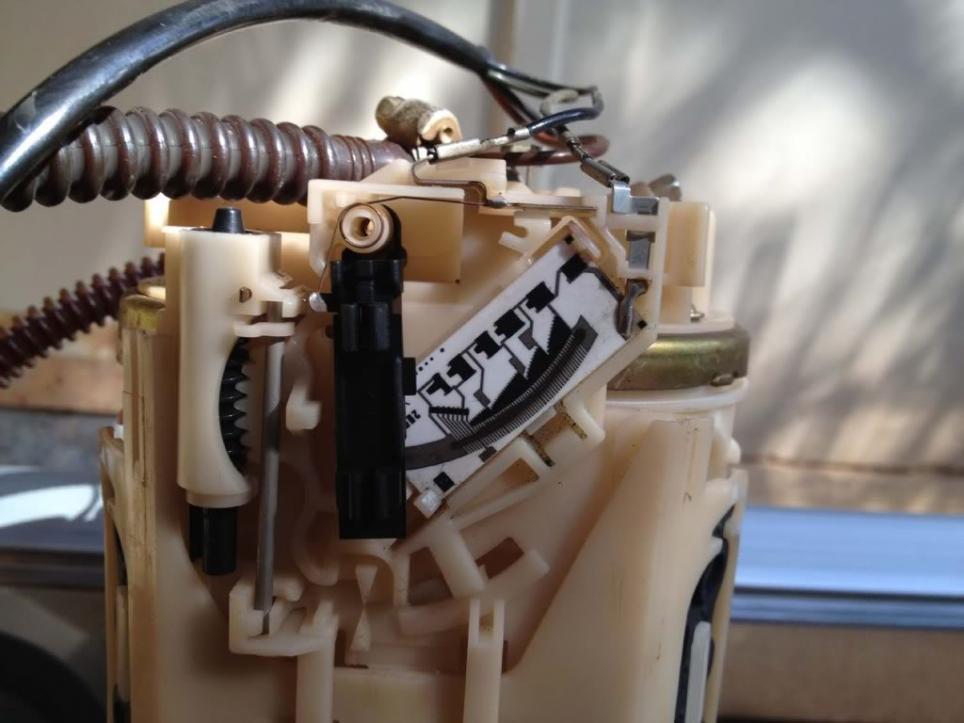

Fuel Filter ........

Polen filter .......

Gear oil ........... 2.0L (Penrite Transxle 75)

ATF ................ G 052 162 A2

Coolant ........... 11.5L (VW G12)

TOW BAR QUESTION

Aftermarket Catalytic Converter http://www.microfreshfilters.com.au/

ENTERING THE RADIO CODE 1998 EURVOX CASSETE RADIO

Feel free to add more information.

Comment