Originally posted by waxgti

View Post

Above Forum Ad

Collapse

Announcement

Collapse

No announcement yet.

Bang for buck fabrication jobs...

Collapse

X

-

I dont really see the point in Fabbing up downpipes, any exhaust place can do it, not too hard

Rather see something a bit more special like control arms or camber plates, things like that. Just do what we did on my car, get a MK4 downpipe cut it a few times and weld it back together

Oh and it has held together better than the APR one didMODS- TOO MANY

Comment

-

I agree with vwthunder re downpipes, any exhaust place can do it, not too hard.Originally posted by vwthunder View PostI dont really see the point in Fabbing up downpipes, any exhaust place can do it, not too hard

Rather see something a bit more special like control arms or camber plates, things like that. Just do what we did on my car, get a MK4 downpipe cut it a few times and weld it back together

Oh and it has held together better than the APR one did

The Strut top Mounts and bearings go early on these Polos and Qld roads do not help!!! Cheers Al

Comment

-

You forget I live in Albury - if it's not Holden or Ford, they point to the door lol. I've had people plain refuse to do work purely because it's a european car...they know nothing about them.I dont really see the point in Fabbing up downpipes, any exhaust place can do it, not too hard2019 132TSI Tiguan

2011 Audi S4 Wagon

1988 MK1 Caddy

2006 Polo GTI

Comment

-

-

Yes, I have certainly found that I have less traction out of turns on my road tyres since fitting the camber plates, although I think the stiffer front ARB I had fitted at the same time also has contributed to this.Originally posted by Bullet Fast View PostJust be aware, narrow tracked vehicles, mac strut front ends and high-ish COGs are going to need a bit of camber to turn best at limit of adhesion which causes some traction issues under hard braking and acceleration in FWD cars.Resident grumpy old fart

VW - Metallic Paint, Radial Tyres, Laminated Windscreen, Electric Windows, VW Alloy Wheels, Variable Geometry Exhaust Driven Supercharger, Direct Unit Fuel Injection, Adiabatic Ignition, MacPherson Struts front, Torsion Beam rear, Coil Springs, Hydraulic Dampers, Front Anti-Roll Bar, Disc Brakes, Bosch ECU, ABS

Comment

-

Well this should be pretty obvious to anyone looking -

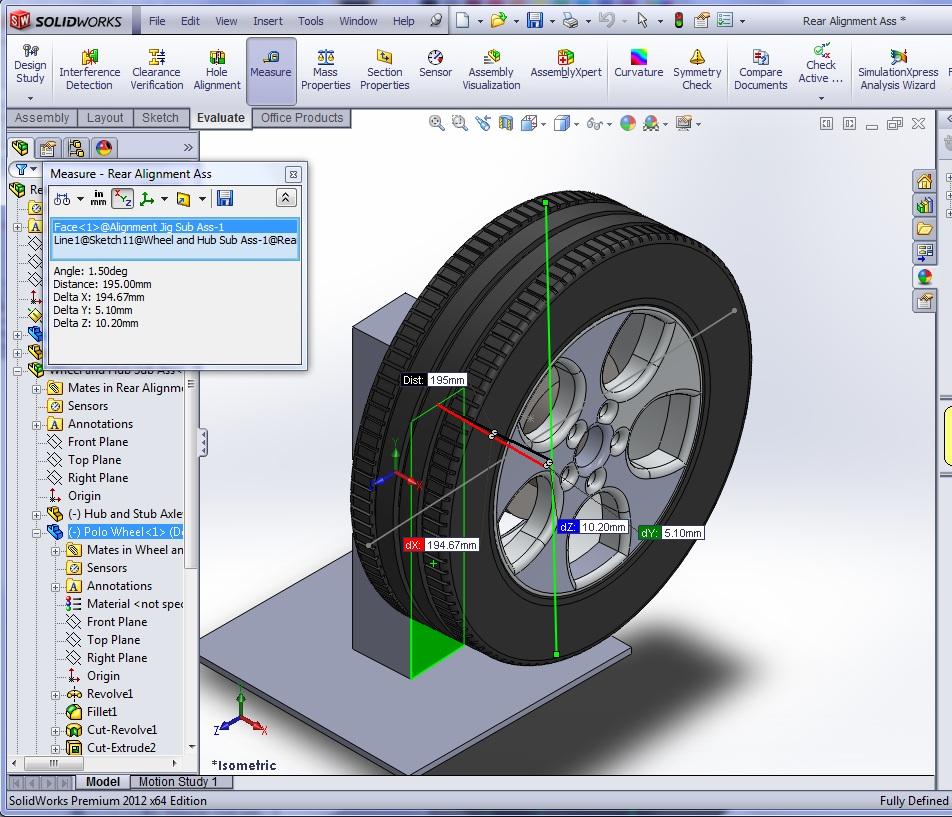

I took the rear end apart measured up a heap of things and modelled it back into solidworks with enough details to run maths off a static loaded model. This isn't the best suite of software for determining suspension geo, but is the best to design parts into it. I'm really not keen of measuring the entire chassis to pull exact roll centres, COGs etc... If someone else wants to do this I'll model the whole car!

Anyway, because wheel alignments come in linear measurements at the rear instead of angular... I had to model everything from the axle out to determine where I could alter things. I have another wheel alignment on Thursday, so once I have a base line I'll feed the stock, albeit lowered figures into Solidworks, and see how much I can gain, and where.

I had to model everything from the axle out to determine where I could alter things. I have another wheel alignment on Thursday, so once I have a base line I'll feed the stock, albeit lowered figures into Solidworks, and see how much I can gain, and where.

As a curiosity, my lower two stub axle bolts sit perfectly parallel to the ground at 662mm (arch to ground) ride height... odd no?

Pretty pictures.

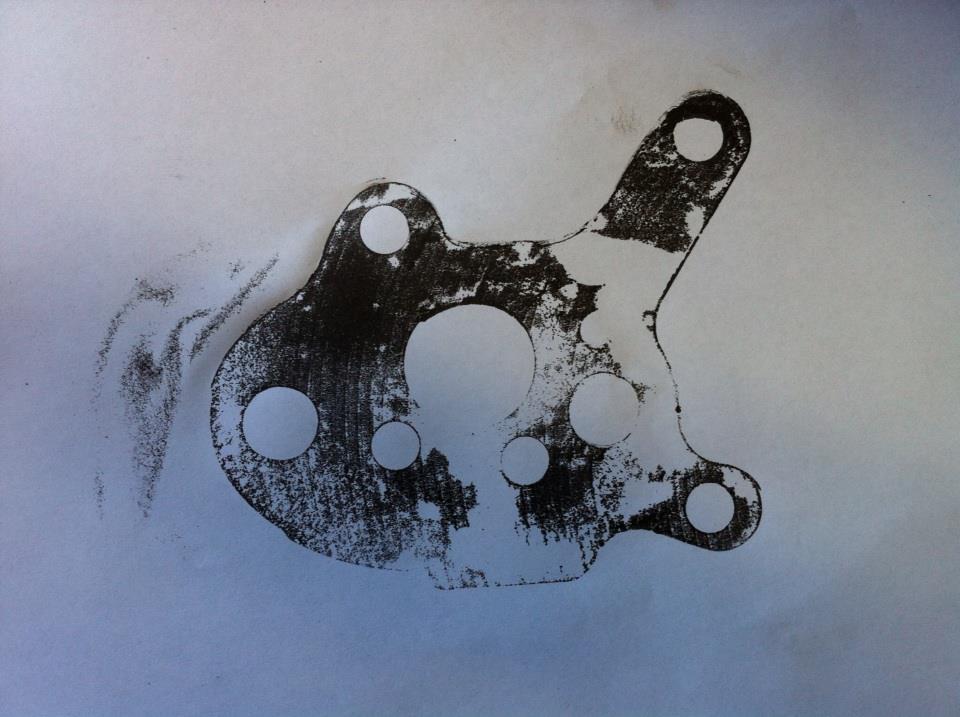

Hub off

Horizontal stub axle bolts?

Masked up - roughly

Touch of paint and voila! Normally I'd use bearing blue for this but I couldn't find any. Just wiped it off. wet.

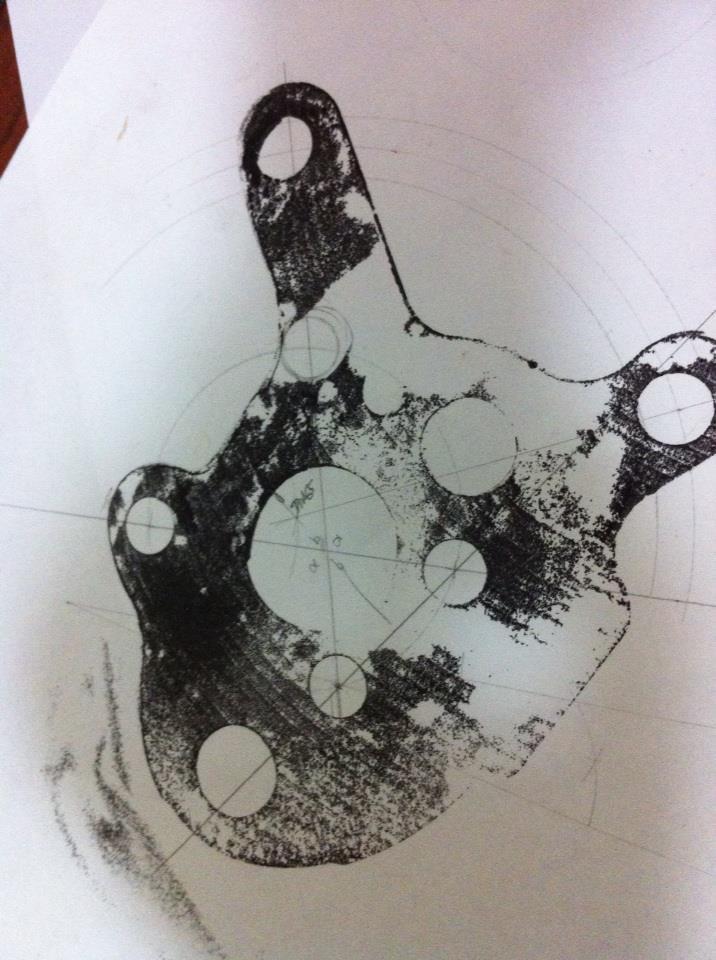

Reverse engineered on paper looking for design intent, angles, concentricities etc - I have to assume the print wasn't perfect, so I'll make a couple of variations initially based on geometric assumptions and adjust from there if it doesn't fit quite right.

Measuring up a couple of bits.

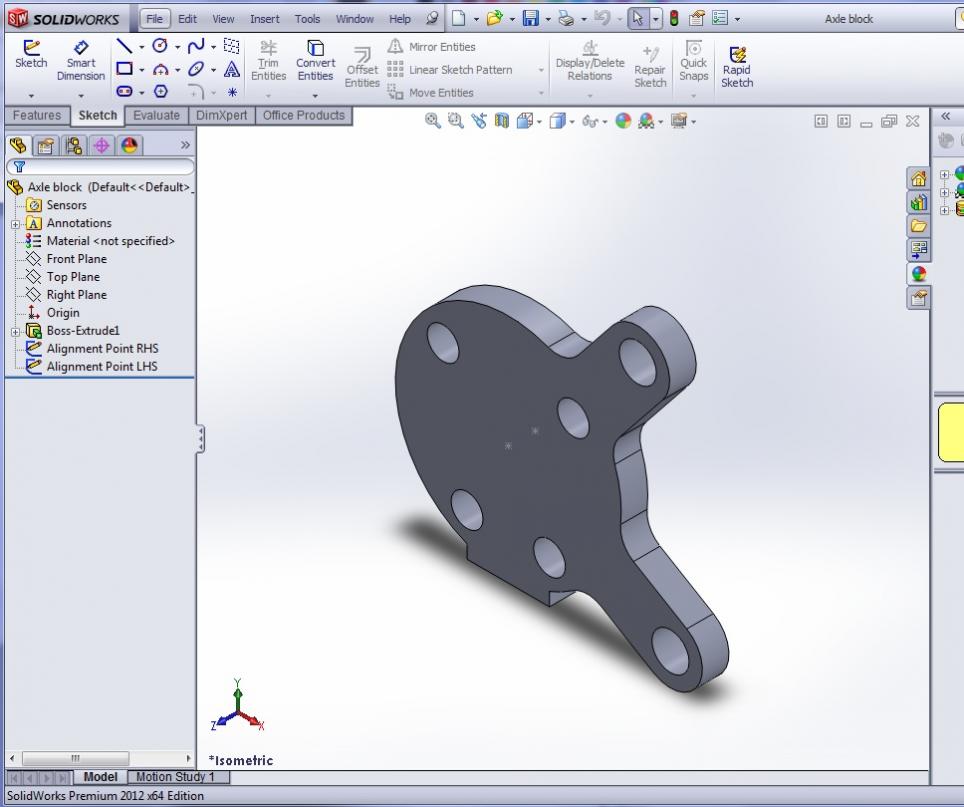

Axle block model.

Wheel mock up on a hub on an alignment jig showing a nominal or stock camber through an evaluation tool. I'll feed my numbers into this after Thursday... I did the wheel cause it made me smile - otherwise the only important dimensions are outter dia and offset...

Last edited by Bullet Fast; 13-01-2013, 03:02 PM.

Last edited by Bullet Fast; 13-01-2013, 03:02 PM.

Comment

2025 - Below Forum

Collapse

Comment