Hi. My POG is a dedicated track/hillclimb car. Based on Sam’s thread I rotated my front strut tops to prioritise caster over camber. The alignment guy thought that I would be better off going back to the original settings, but I’m not so sure? What do you track guys reckon?

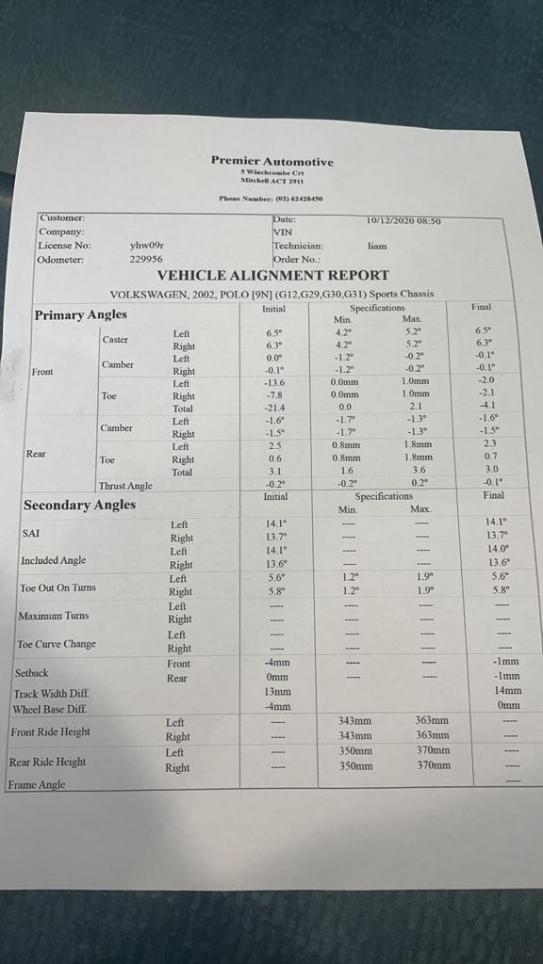

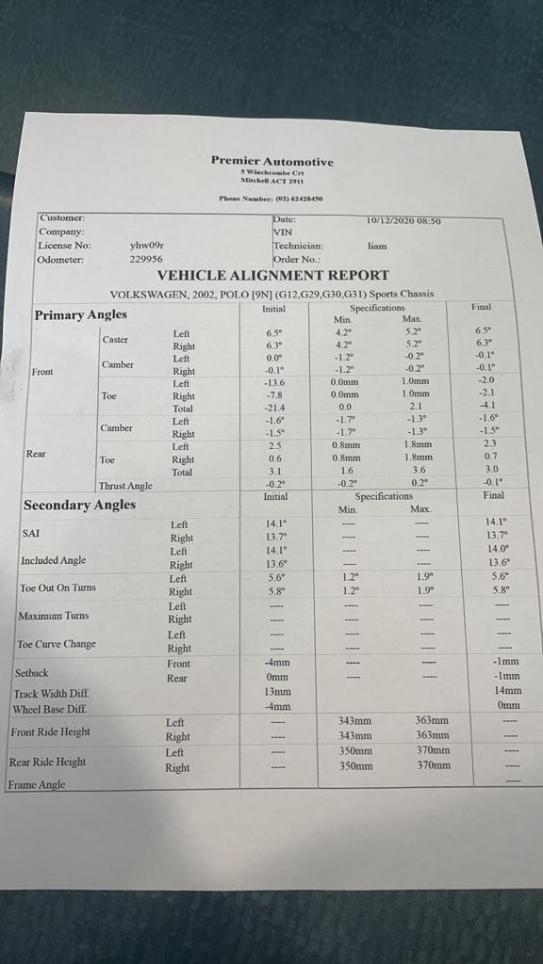

Latest settings attached.

Sent from my iPhone using Tapatalk

Latest settings attached.

Sent from my iPhone using Tapatalk

Comment