It’s been a while but I’ll try and let the pictures do the talking on the limited progress

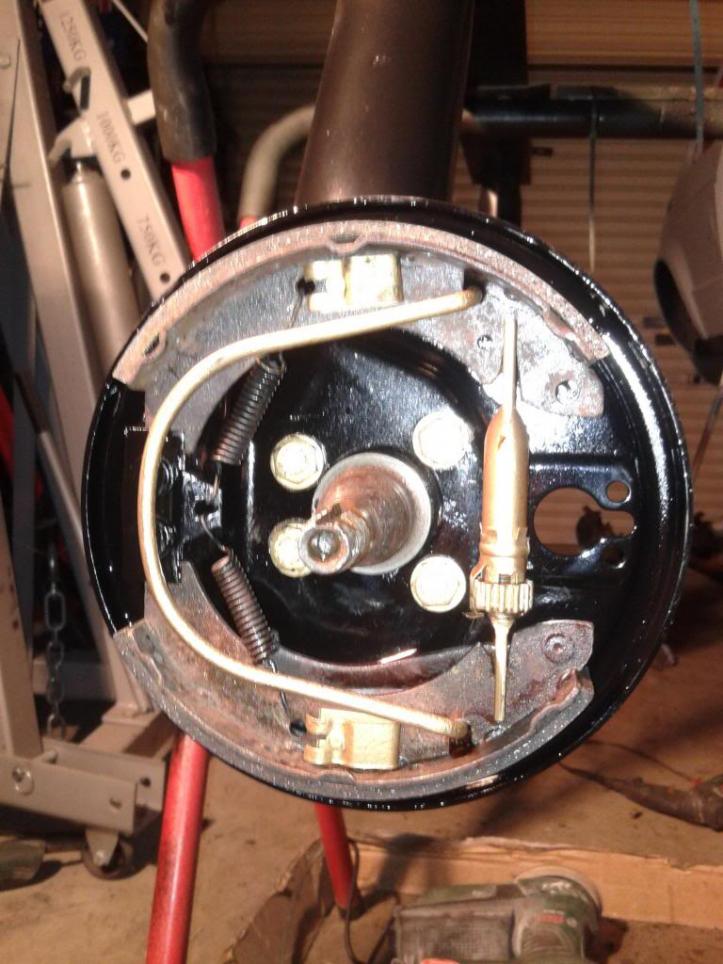

I had some rust on the RHS Sill outer, managed to cut the rust out, repair with new steel and paint the inside of the sill while I had access.

I made the repair it two sections to prevent any distortion in the sill.

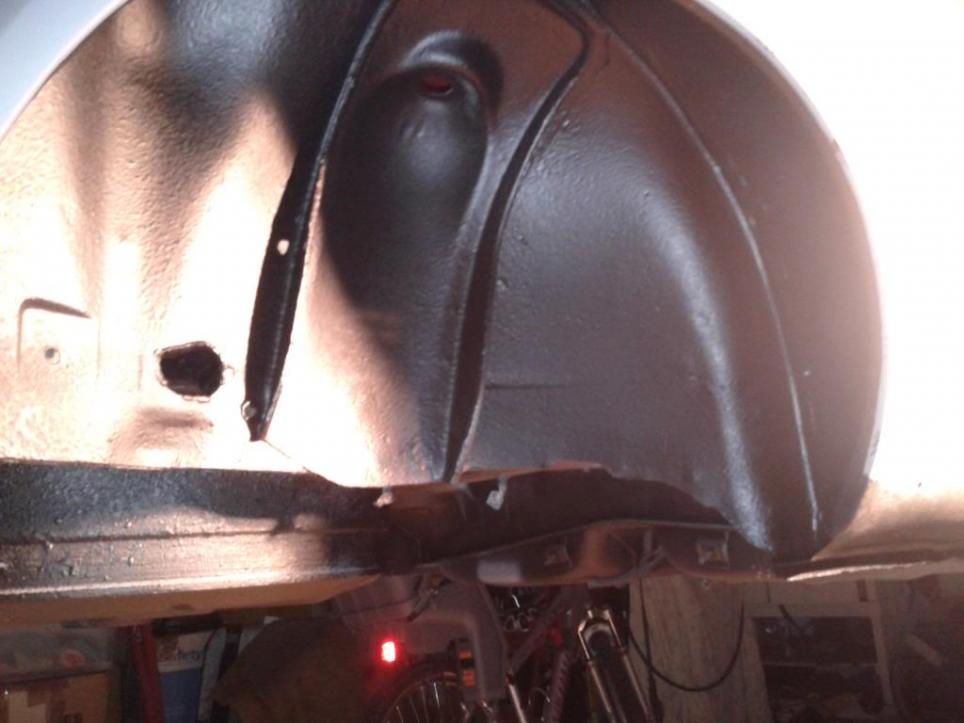

Inside the painted sill

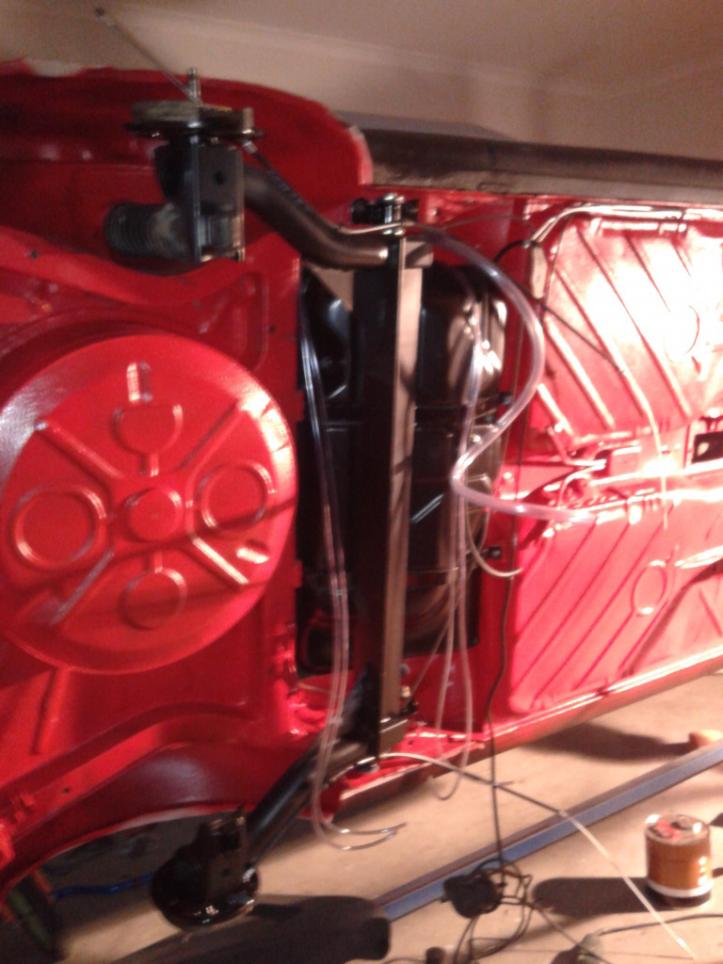

Once I finished the sill repair I wanted to finish getting the body back to bare metal, 80 grit sand, then etch and 2-3 cots of primer. I’ll only start sanding the primer once I get round to the painting stage.

I know these back corners can rust out from the inside out so I carefully cut a section out to check, repair if needed clean and paint before welding the section back in. It turned out the LHS was is great nick but the RHS needed repair.

I had some rust on the RHS Sill outer, managed to cut the rust out, repair with new steel and paint the inside of the sill while I had access.

I made the repair it two sections to prevent any distortion in the sill.

Inside the painted sill

Once I finished the sill repair I wanted to finish getting the body back to bare metal, 80 grit sand, then etch and 2-3 cots of primer. I’ll only start sanding the primer once I get round to the painting stage.

I know these back corners can rust out from the inside out so I carefully cut a section out to check, repair if needed clean and paint before welding the section back in. It turned out the LHS was is great nick but the RHS needed repair.

Comment