Originally posted by Mischa

View Post

Above Forum Ad

Collapse

Announcement

Collapse

No announcement yet.

Turbo high flowing!!

Collapse

X

-

HA HA! My mums mk1 is faster than your car for at least the next year before you get yours running.....Originally posted by Preen59 View PostHaha i've seen all this stuff. Many times.

I'd rather my carbied NA engine though....

sigpic

sigpic

Mk2 GTI 2 door 1.9l 8v turbo 1st mk2 1st engineered water vw nats 09

Mk1 twin eng twin turb

scirocco gti 2.1l 16v turb 6spd

Audi A4 B5 1.8t

Comment

-

Yeah whatever. I'm getting there..Originally posted by twin eng, twin turbs View PostHA HA! My mums mk1 is faster than your car for at least the next year before you get yours running.....

APR Tuned | KW Suspension | INA Engineering | Mocal Oil Control |

Website: http://www.tprengineering.com

Email: chris@tprengineering.com

Comment

-

I'll get photos of all this stuff and post it next week seeing as marty will never get round to it. '11 Golf GTI - Tornado Red, 5dr, DSG, 18" Detroit's, ACC, Sunroof, Park Assist, RVC, Tint, Leather, Electronic Seat

'11 Golf GTI - Tornado Red, 5dr, DSG, 18" Detroit's, ACC, Sunroof, Park Assist, RVC, Tint, Leather, Electronic Seat

previously: '00 audi a4 turbo quattro avant, '89 audi 90quattro20v, '78 golf 1.8l

Comment

-

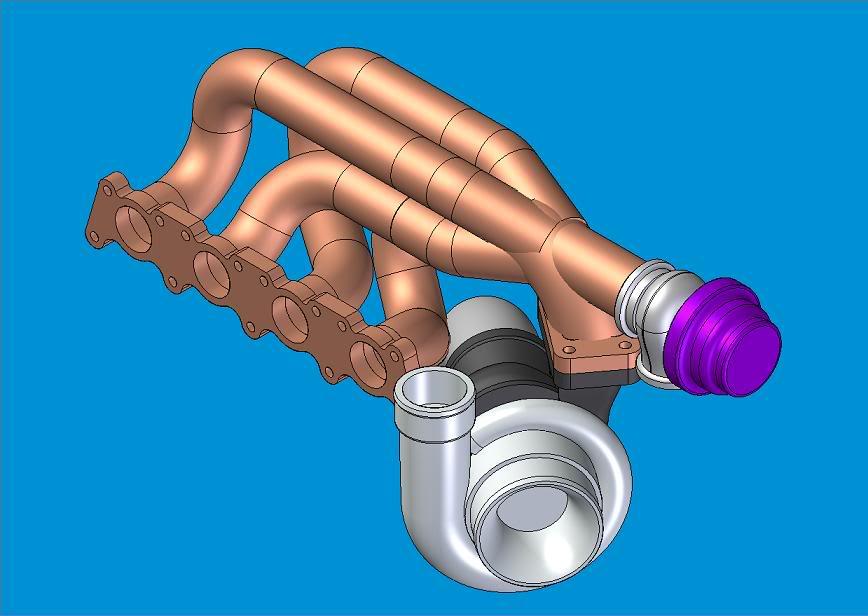

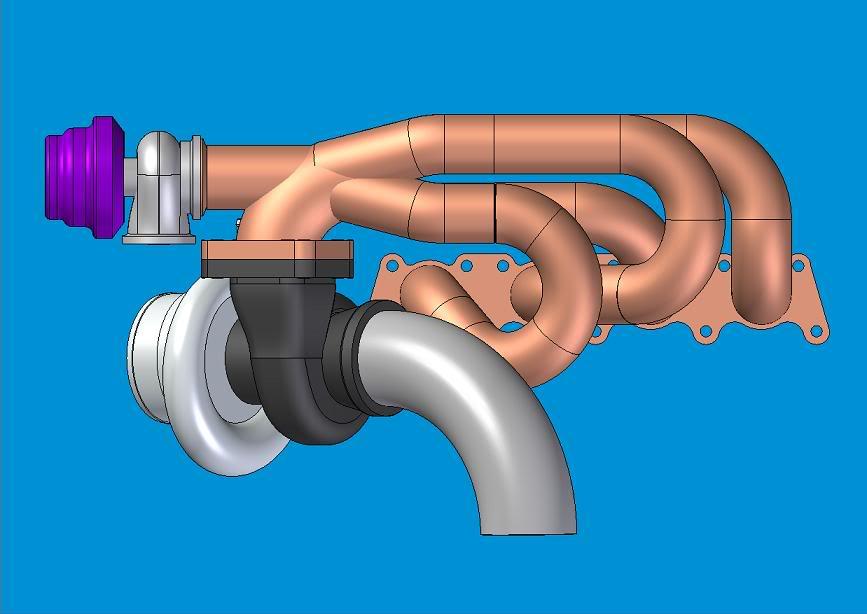

Ha! heres some photos then, Starting with the massive turbo that will be helping make the 500hp goal power output from my 2.1 litre 16v.Originally posted by richo View PostI'll get photos of all this stuff and post it next week seeing as marty will never get round to it.

sigpic

sigpic

Mk2 GTI 2 door 1.9l 8v turbo 1st mk2 1st engineered water vw nats 09

Mk1 twin eng twin turb

scirocco gti 2.1l 16v turb 6spd

Audi A4 B5 1.8t

Comment

-

Heres a shot of the 4" coned outlet on the well modified exhaust housing sitting on the 16v turbo manifold i made from scratch. You can see the ports which are polished all the way through on the manifold with webbing welded all the way between the runners to prevent any warping under the high temperatures it will endure causing leakage at the gasket to the head. I will get the manifold and exhaust housing high temp coated in the future... What isn't pictured is the 38mm tial wastegate to go with it all..sigpic

Mk2 GTI 2 door 1.9l 8v turbo 1st mk2 1st engineered water vw nats 09

Mk1 twin eng twin turb

scirocco gti 2.1l 16v turb 6spd

Audi A4 B5 1.8t

Comment

-

Heres the custom inlet manifold i fabricated. The runners are 56mm diameter at the plenum with bellmouthed ends tapering down to the oval shape to suit the ports of the head. At the head they are 6mm bigger in diameter than stock and ported, polished and port matched with dowels fitted so once in place the join is smooth without any step at all. The plenum is 100mm diameter tapering off at the end and i am currently machining up a billet 80mm throttle body to suit the manifold so they are matched. I will polish all of this once finished.sigpic

Mk2 GTI 2 door 1.9l 8v turbo 1st mk2 1st engineered water vw nats 09

Mk1 twin eng twin turb

scirocco gti 2.1l 16v turb 6spd

Audi A4 B5 1.8t

Comment

-

Nice work.

What model/spec is that turbo?

I like the pipe expansion. Just like a expansion chamber on a motorbike. My friend used this style on a FJ20 with a GT3540 in a mk1 escort with huge success & power too!

Just for interest sake, I personally wouldn't web a hig hp turbo exhaust manifold like that.

They do expand a fair bit & if there contained like that, they will crack elsewhere & in a bigger way. they'll also crack the hell out of the ceramic coating.

My race 4-1 pacemaker's on my old ute with high temp coating even cracked under the temp. put on it in a burnout comp!

The flange & stud holes should also be cut & separated from each runner for the same reason.

Comment

-

I used 4mm wall thickness mild steel steam pipe bends for the runners for good reason. On my 1.8t audi a4 i made a similar manifold running a GT 25/40 turbo without any problem for years. Its so solid that it dosn't warp or crack. My mk2 has a similar set up with water cooling around the turbine flange which has kept the temps down preventing any cracks or gasket issues. After having made stainless manifolds in the past with thinner wall thickness (1.6mm) i have had issues with them cracking and flanges warping causing leaking gaskets. Thats why i make mine from mild steel with much thicker wall thickness.Originally posted by golfworx View PostNice work.

What model/spec is that turbo?

I like the pipe expansion. Just like a expansion chamber on a motorbike. My friend used this style on a FJ20 with a GT3540 in a mk1 escort with huge success & power too!

Just for interest sake, I personally wouldn't web a hig hp turbo exhaust manifold like that.

They do expand a fair bit & if there contained like that, they will crack elsewhere & in a bigger way. they'll also crack the hell out of the ceramic coating.

My race 4-1 pacemaker's on my old ute with high temp coating even cracked under the temp. put on it in a burnout comp!

The flange & stud holes should also be cut & separated from each runner for the same reason.

Turbo is based on a GT35r with modified housings, ported and polished for improved flow etcsigpic

Mk2 GTI 2 door 1.9l 8v turbo 1st mk2 1st engineered water vw nats 09

Mk1 twin eng twin turb

scirocco gti 2.1l 16v turb 6spd

Audi A4 B5 1.8t

Comment

-

Originally posted by twin eng, twin turbs View PostI used 4mm wall thickness mild steel steam pipe bends for the runners for good reason. On my 1.8t audi a4 i made a similar manifold running a GT 25/40 turbo without any problem for years. Its so solid that it dosn't warp or crack. My mk2 has a similar set up with water cooling around the turbine flange which has kept the temps down preventing any cracks or gasket issues. After having made stainless manifolds in the past with thinner wall thickness (1.6mm) i have had issues with them cracking and flanges warping causing leaking gaskets. Thats why i make mine from mild steel with much thicker wall thickness.

Turbo is based on a GT35r with modified housings, ported and polished for improved flow etc

Makes perfect sense.

The watercooling idea sound's like a beaut too. Would like to see some pic's of it.

I'm not a big fan of the stainless gear either.

All the the stuff I've been involved with has also been steam pipe straight from Reece plumbing. Strong, easy to work with & almost every bend you could ever need.

This is how I'd like mine setup on the "one day" 20vt.

Have the turbo hanging off the side, on top of the gearbox, shortening the pressure piping by at least a foot, reducing the exhaust down pipe radius & also being able to get fresh air straight into it.

Only draw back is relocating the booster/master cyl. assembly remotely.

Comment

-

That looks awesome! you have been putting a lot of thought into this... I made a similar manifold setup on a nissan ET pulsar running a CA18DET with a t3/t4 though the exhaust was at the front the 3" down pipe i had going over the gearbox and down.

One thing to consider is manifold length although tuned length is good the longer the runners are the less heat energy and pulse from the exhaust stroke hits the turbine. Shorter runners will have improved low end response but dont flow the top end nearly aswell as longer tuned length manifolds.sigpic

Mk2 GTI 2 door 1.9l 8v turbo 1st mk2 1st engineered water vw nats 09

Mk1 twin eng twin turb

scirocco gti 2.1l 16v turb 6spd

Audi A4 B5 1.8t

Comment

-

Autodesk Inventor CAD model?

APR Tuned | KW Suspension | INA Engineering | Mocal Oil Control |

Website: http://www.tprengineering.com

Email: chris@tprengineering.com

Comment

-

Nah matey.Originally posted by Preen59 View PostAutodesk Inventor CAD model?

Didn't mean to fool both of you.

Christ I'm not that good on a computer. Can't even circle item's in pic's or draw arrow's on photoshop!!!!

Found the pic somewhere, like the idea, design & thought it would work really well on a golf, due to turbo, intercooler & intake placement.

I didn't really matter about the tuned length runner's or the length. More placement.

I learn't from a friend who has alot do do with rotary's, that if it's all smooth & no sharp kink's, it doesn't matter about if there the same length or not. It will still work!

Look at how much power can be made on standard early headed cast holden v8's exhaust manifold's with a single turbo. 600+hp is easily achievable!

It's to run a GT3076R with a .82AR ex. housing by the way.Last edited by Oneofthegreats; 02-10-2008, 12:17 AM.

Comment

-

Looks like an auto-desk inventor jobbie, would love to see that in real life!80,000km 1997 MK3 VR6 manual for sale - www.vwwatercooled.org.au/forums/f23/80-000km-1997-manual-vr6-nsw-sydney-67658.html

Comment

2025 - Below Forum

Collapse

Comment